I tested the subsequent layers only after removing them from the template. I was worried that I might have damaged some of the joints when removing the LEDs, so I tested this layer again once I removed it from the template. I then carefully removed the layer of LEDs from the template, trying not to bend the legs of the LEDs. I was glad I did this as I found two bad connections on my first layer. I used a small battery pack for this and just ran the leads over the columns and rows, checking that each LED lit up.

I then tested the LEDs again, this time testing the soldered connections. I continued this until all of the columns and rows on this layer were connected. In hindsight, these legs should have been bent in the opposite direction in order to keep the connections on the back side of the cube when it’s on display, but this isn’t particularly noticeable in the end. I used a pair of pliers to space the bend a little away from the back of the LED so that the positive connections were spaced about a millimeters away from the negative connections. Once all of the negatives were done, I did the positives. I started with the negatives, bending them all down so that there was some overlap between them. Next, the idea is to connect all of the positive legs together in each column and all of the negative legs together in each row, making sure that they don’t touch each other. So with the longer positive leg or anode on the right side and the negative leg, or cathode on the left side. I then layed out the 64 LEDs on the template, making sure that the LEDs were all facing the same direction. I cut two layers, one with 3mm holes to hold the LEDs and one with 5mm holes to be the bottom spacer layer so that the LEDs don’t touch the table underneath them when they’re pushed into the template. Rather than trying to get the placing right for each individual LEDs, having an MDF board which I could press the LEDs into and then connect up while they’re held in place would dramatically speed up the process and hopefully result in nice straight and evenly spaced grids of LEDs. Next, I laser cut a template to lay out the LEDs. I didn’t find any faulty LEDs, but I still think it was worthwhile to save the frustration if I had. I set up a simple 5V power supply and 220 ohm resistor on a breadboard and got testing.

I’ve never found a new LED to be dead, but since they said that they included 550 LEDs in case some were faulty, I decided to test them all first to avoid have to replace LEDs once it was all assembled. I started out by testing all of the LEDs.

8X8X8 RGB LED CUBE ARDUINO KIT SOFTWARE

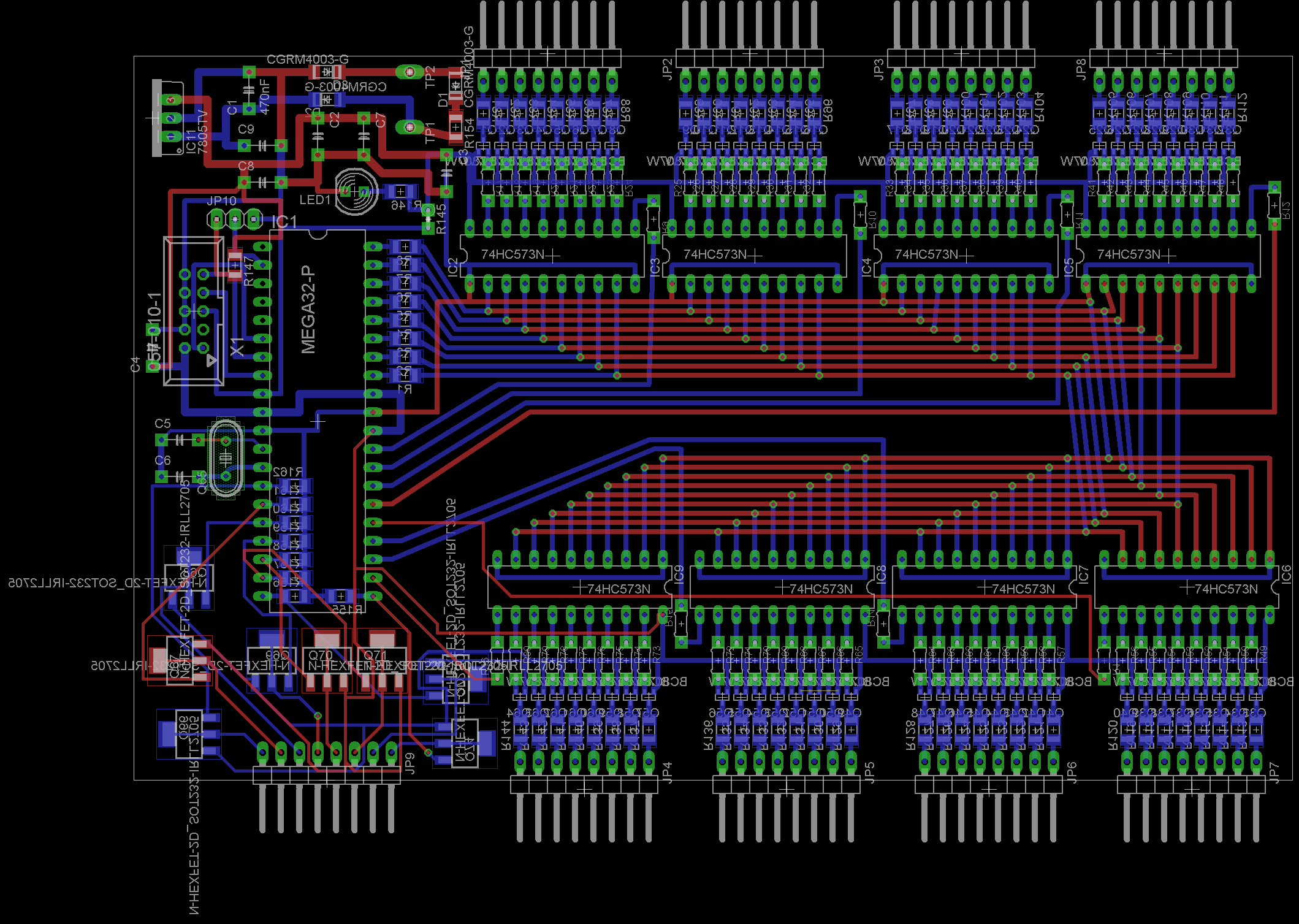

There is guide a good guide and software to re-programming the STC micro-controller on GitHub. You’ll need a USB-2-TTL programming module to re-flash this micro-controller. The product page said that the cube was Arduino compatible, although the chip supplied is a STC12C5A60S2 micro-controller. There was a bag of LEDs, they said that 550 LEDs are supplied in case some are faulty, the PCB to mount the components, and then a small case with the chips and other electronic components. The kit arrived quite quickly and this is what was delivered. So let’s get started with putting the cube together. 8x8x8 LED Cube Kit (Better Quality, Not Arduino Compatible) – Buy Here.8x8x8 LED Cube Kit (Like The One In The Video, Probably Has No Instructions Either) – Buy Here.

0 kommentar(er)

0 kommentar(er)